Additive Manufacturing – The Here, The Near, And The Future

Additive News • August 25, 2019

The here

Additive manufacturing is not the future – it’s now. Right now. From aerospace to hand tools, automotive to healthcare, additive manufacturing (i.e. 3D printing) is changing the world.

That’s not hyperbole, it’s a well-established fact supported by studies, industry experts, and the proven ROI from businesses across the globe. Many companies are already using additive manufacturing in production, and 80% of those companies say it is already helping them prototype and innovate faster.

Companies large and small are hiring additive manufacturing experts and engineers, and colleges near and far are introducing courses dedicated to additive design.

You don’t have to look far to see that even the titans of industry have seen the light. Right now in Hartford, Stanley Black & Decker and TechStars are hosting its second cohort of 10 additive manufacturing startups.

That’s today, not in some far-flung tech metro, but right down the road in humble Hartford, CT.

Now try to imagine what your industry might look like in 10 years, and how 3D printing would be integrated.

Because it isn’t a matter of IF additive manufacturing can improve your business – it’s just a matter of HOW.

Enter Additive Experts

That’s where we come in.

At Additive Experts, the name says it all – we’ll be your consultants, your designers, and your manufacturer for all things 3D printing. We know the pros and cons, the ins and outs, and everything in-between when it comes to additive manufacturing from the biggest names in the game.

Interested in adding additive manufacturing to your business? We will identify the areas where additive manufacturing will benefit your business the most, and what machines are right from the job. We sell and service the latest offerings from Desktop Metal, Markforged, Formlabs

and more – and because we use those same machines every day, you’ll get the real rundown, not some salesy schtick.

Need to an additive designer? You’re at the right place – whether you’re starting from scratch, or want to convert an existing design to additive manufacturing, we can take you across the finish line.

Ready for production? We’re ready for you. Whether it’s composite, fiberglass, or metal, we have the tools and capacity for printing your product en masse. Our machines run 24/7/365 and can print even the most complex pieces under the right guidance (i.e. ours).

This is everything that’s happening today, and barely scratches the surface of what’s in store

The Near

When we talk about what’s just around the corner for additive manufacturing, it seems more like science fiction than reality. Then again, we’re already printing impoverished people new limbs, so it’s really not that crazy.

In the next year or two, the first large scale 3D printer farms will come online to print mass runs of products. The auto industry has warmed to additive manufacturing, and its use will expand from a few specialty parts on exotic cars such as the Bugatti Veyron to “tens of thousands of parts” over the next few years.

Short-run manufacturing will become more viable as print farms replace the need for expensive tooling. This means specialty parts manufacturers will start to feel the squeeze as their monopoly is chipped away.

The U.S. military will make greater use of additive manufacturing for replacement parts on jets, tanks, and other war machines. It might start with toilet seats, but it surely won’t stop there.

The use of 3D printing in healthcare systems for prosthetic limbs, dental reconstruction, patient-specific organ models, and more, will become commonplace.

That’s not even discussing the advances and improvements additive manufacturing companies themselves will offer. The tech will get cheaper, faster, and better in every way – and companies that invest early can realize huge savings in short order. A single $35,000 3D printer saved GM over $300,000 at just ONE of its auto plants.

Imagine what it could do for your company?

In short, the next two years will see additive manufacturing become far more mainstream – and far more effective.

The Future

Make no mistake – additive manufacturing is the future of ALL manufacturing. The advantages are many, and the investment and improvements in the technology ensure that it will soon surpass traditional manufacturing techniques at almost every level.

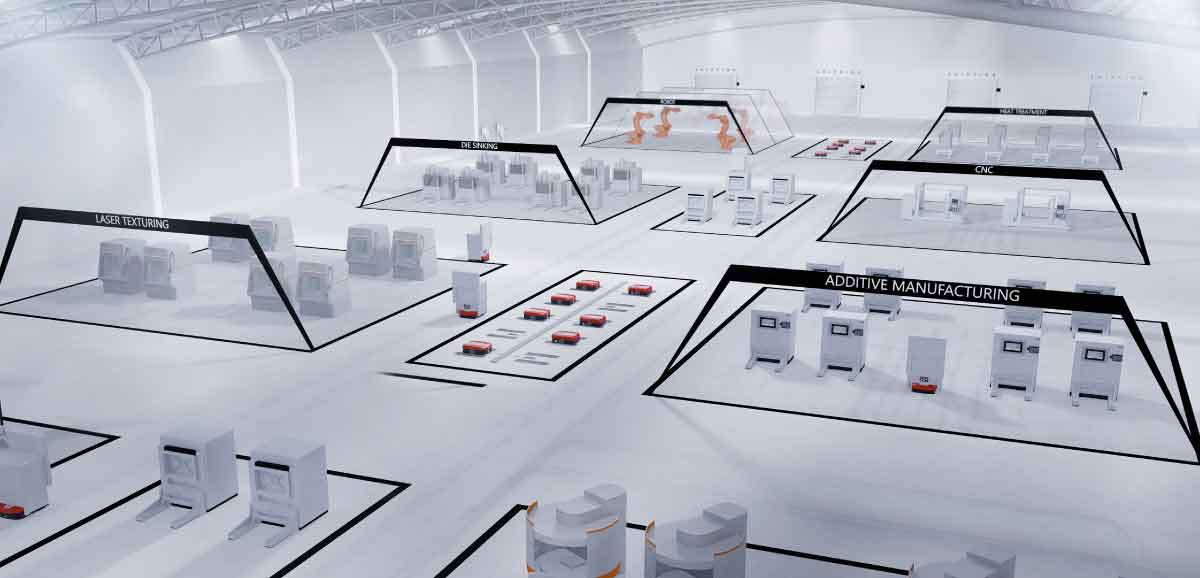

Automation and additive manufacturing go hand-in-hand, and though it may seem like science fiction, the day of fully automated, totally flexible 3D printing farms is probably closer than we think.

Artificial Intelligence will aid in design and production, finding potential flaws or cost savings where humans don’t and bring even greater efficiency to additive manufacturing operations.

3D printing will make prototyping and small-batch manufacturing far more accessible to individuals, lowering the barrier of entry and leading to a new age of innovation and invention.

For businesses, prototyping costs will similarly plummet, freeing more resources for innovation, marketing, or expansion. The time it takes to build a prototype will also be shortened, allowing for a quicker ROI on R&D. In-house manufacturing will become far more attainable for mid and small-businesses as costs come down and technology improves.

Additive manufacturing can also keep machines and businesses running longer. Porsche, for example, is already 3D printing certain vintage vehicle parts in quantities large enough to satisfy demand without investing in expensive tooling. Imagine being able to print a replacement part, instead of going to the store?

Because if we look far enough ahead, there will come a day when 3D printers are every bit the home appliance that refrigerators and toilets are today. On a larger scale, 3D printers would streamline auto production, and Amazon warehouses could become micro-factories for all your unneeded consumer goods.

The Now

Additive manufacturing is the engine of the next industrial revolution (Industry 4.0), and its applications are truly limitless. Our knowledge and experience help us identify opportunities to streamline production and reduce costs through intelligent use of additive manufacturing. We’ll help you find the right machine, at the right price, whatever your business needs may be.

Not quite ready to commit, but still want to take advantage of everything additive manufacturing has to offer? Our consulting, design, and production services are priced to allow you to realize the benefits of additive manufacturing and become partners in the business of the future.